Rubber & Silicone Components

Engineered Rubber and Silicone Components

WELD2CAST Engineering product range also include engineered Moulded Rubber & Silicone Components for any application that you need.

Moulded rubber & silicone parts are produced in one pressing operation. Whether the process is press, transfer or injection moulding we find the best option depending on number of pieces, quality, economy, and geometry of the article.

WELD2CAST have a strategic partnership with the Danish company RubiNord A/S there is specialist within Engineering, Design and Supply of Rubber and Silicone Components and have more than 30 years of experience in the rubber industry.

Our material capabilities for Rubber and Silicone Components includes EPDM, NR, NBR, SBR, Viton, AEM, CR, Silicone, all in hardness in Shore from 20° – 90° and can be designed in color options.

General tolerances for Moulded Rubber & Silicone Components are supply acc. to ISO 3302-1:2014 – Class M1 M2 and M3. Tolerances are greatly affected by part geometry and type of material.

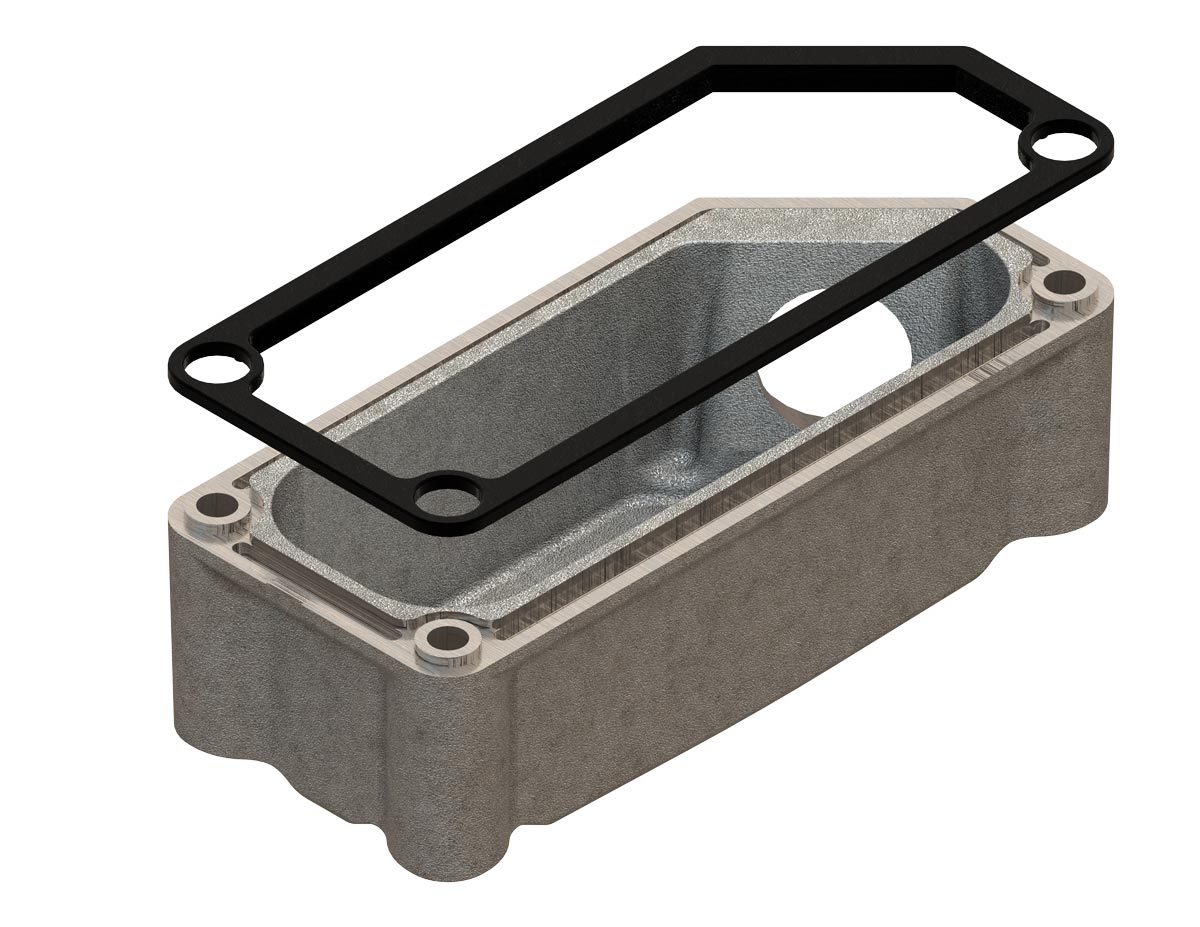

Together with RubiNord A/S we offer our customer an “One Stop Solution” for all types of moulded OEM-components. Together with metal parts, Castings or Forgings, we design and advise about gaskets, seals, plugs, membranes, buffer or dampers, for your complete product.

You can learn more about RubiNord A/S and WELD2CAST “One Stop Supplier” solution by visiting RubiNord’s website www.rubinord.dk or download our brochure RubiNord(English).

Your Key Advantages of WELD2CAST & RubiNord Combined Engineering Metal, Rubber & Silicone Solutions

- ONE Innovation Partner for ALL Your Engineering Metal and Rubber Components.

- Over 50 years of combine technical experience.

- Reduce total cost, better transparency, and improved flexibility.

- One specialist contact with skills and experience about your business, applications and needs.

- Reinsurance correct quality and correct product the first time.