Metal 3D Print Additive Manufacturing

Metal 3D Print Additive Manufacturing Services For Product Developments and Rapid Prototyping Supply!

3D Metal printing is the latest capability in our product development department. It allows a very flexible and low-cost production of prototype parts with incredible detail on tolerance -/+ 0,1 mm, possible to supply in many varieties of material: Aluminium, Stainless, Inconel, Tool/Carbon Steel and Titanium.

The benefits of the process are clear in the early stages of a project. A physical and dimensionally accurate Metal component can be printed in metal and handed to the client, as an illustrated and real-time part in casted or forged design state. This allows our clients to implement into a sub-assembly for final suitability testing.

With Metal 3D Print Additive Manufacturing, our engineers get a real-life version of the product to study, improve, and optimize, and therefore is one of WELD2CAST’s key tools in development when converting of weldments or machined solid- assemblies into cost-efficient engineered casting or forgings.

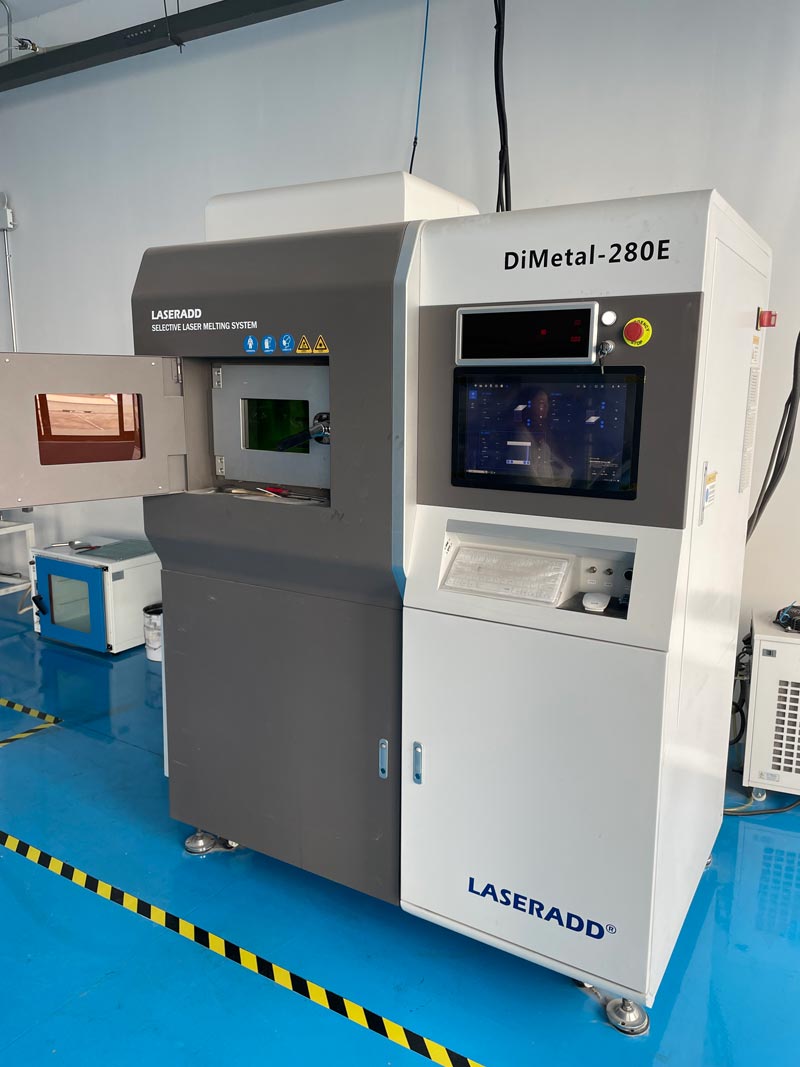

WELD2CAST 3D Metal Printing Capabilities:

- No minimum order quantity.

- Size max: 280x280x360 mm (Build area)

- Minimum of material waste while maximizing strength of components

- Material possibilities: Aluminum (AlSi₁₀Mg), Stainless(SS316L), Inconel(IN718), Tool/Carbon Steel (C465) and Titanium(Ti₆Al₄V)

- Layer thickness: 0.04 – 0.09 mm (Material dependent)

- Very Cost efficiency, Prices starting as low as 50 €/Pieces.

- Our 3D Printing technology is Selective Laser Melting (SLM)

- Serie production options.

- Enables production of challenging components

- Tolerance ± 0,1mm of precision

- Possibilities for very thin feature like 1 mm, Performance grade: 0.5 mm

- Surface roughness < 3,2 µ - Add value option: Finish Machining (treads) and surface treatment finishing.

We provide 3D Printed engineered metal components within 5-7 workings days!