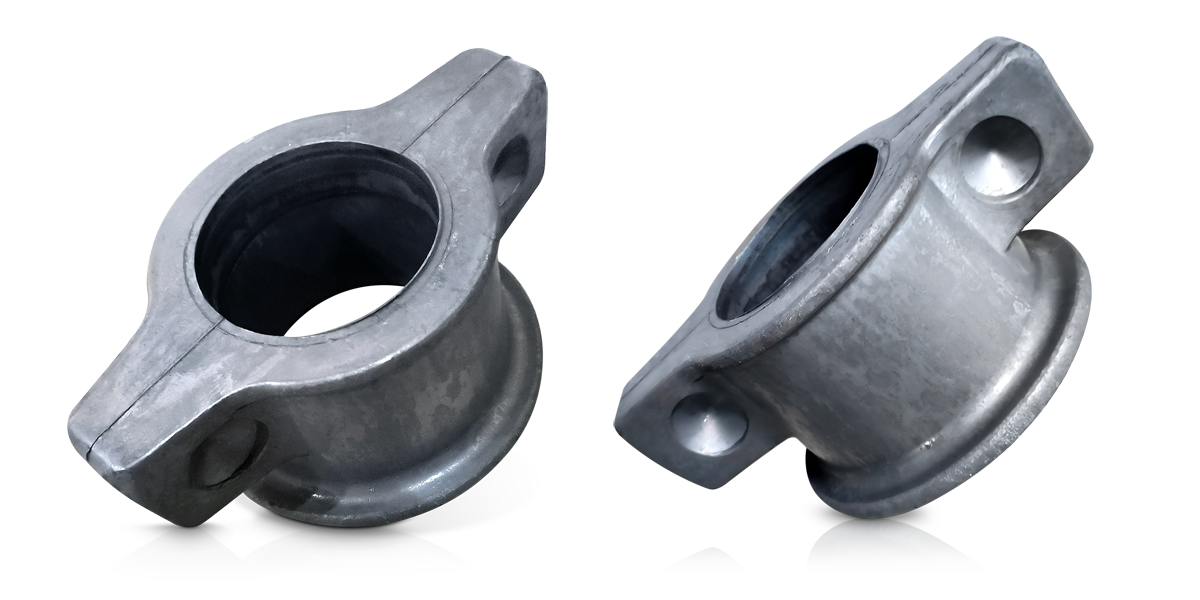

Multi Direction(3D) forgings

Why Choose Multi Directional(3D) Forgings ?

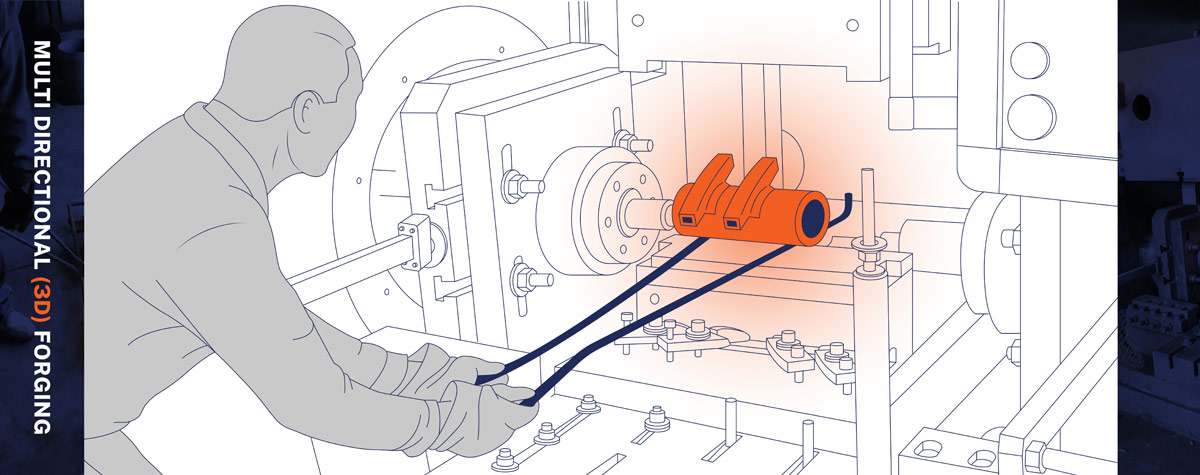

Multi directional Forging is a technology is very unique 3D forgings method consists of a forging process that allows two-way(vertical and horizontal) forging hydraulic press to perform split die forging.

Multi-directional forging offers several advantages, tighter Geometri Forging tolerances LEVEL ( E) acc. standard EN/ISO 10243-2 and also no draft angel needed, can be as low as 0,1°, can be active with this exceptional precision forging technology.

Furthermore improved mechanical properties, enhanced material utilization, and the ability to produce complex shapes with minimal machining

All material that suitable for traditional 2D forging are also suitable for Multi Directional(3D) Forging, such as Carbon steel, alloy steel, stainless steel.

The simple structure and long service life of the mold are beneficial for reducing the cost of forging.

The possibilities for high complex shaped forgings make it ideal for industries like Hydraulics, pump and machine building applications.

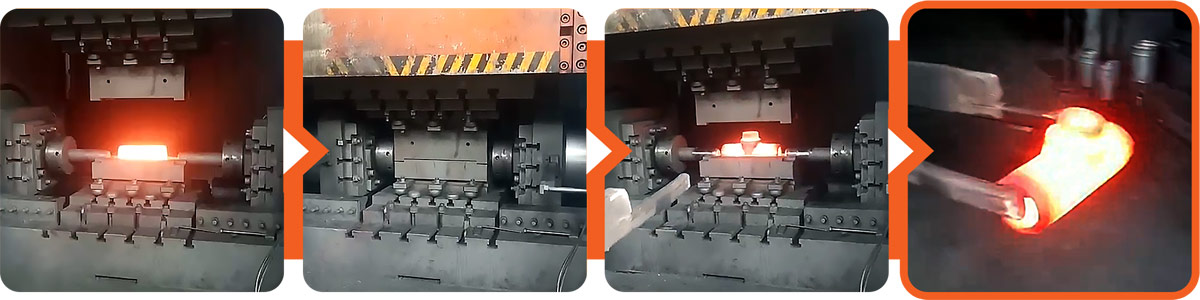

THE MULTI DIRECTION FORGING PROCESS

WELD2CAST’s MULTI DIRECTION (3D) FORGINGS Benefits Include:

- Suitable for forging ranging from 1 kgs to 30 kgs.

- Maximum size: 300 L x 300 W x 300 H mm

- Without flash /rest material to remove, like for Close Die 2D forging, saving on 15-20% in raw material.

- Most ferrous metals can be forged, including carbon, alloy, superalloy, and stainless steel.

- Almost no draft angel need, can be as low as 0,1°

- Lower and simpler hot metal billet need for the Multi Direction forgings process

- Possibilities to eliminate need for secondary machining after Forging

- Can active tighter Geometri Forging tolerances acc. standard EN/ISO 10243-2

- Long service life of the Dies and molds wish equal to reducing the cost of forgings

- More smoother raw surface than normal forging, eliminate manual grind work to remove flash/rest materials.

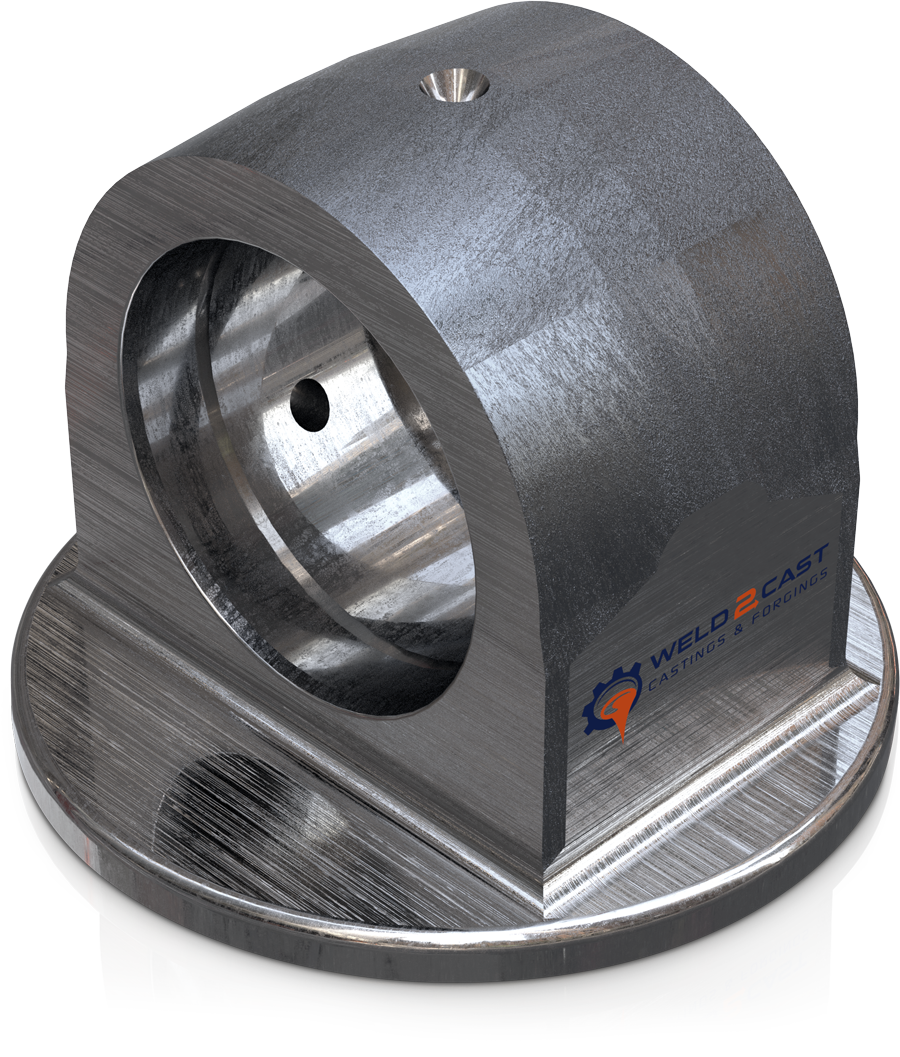

CASE STUDY

High alloy Carbon forged steel part in material 42CrMo4 made be Multi Directional (3D) Forging