Investment Casting (Water Glass Process)

Why Choose Investment Water Glass Casting?

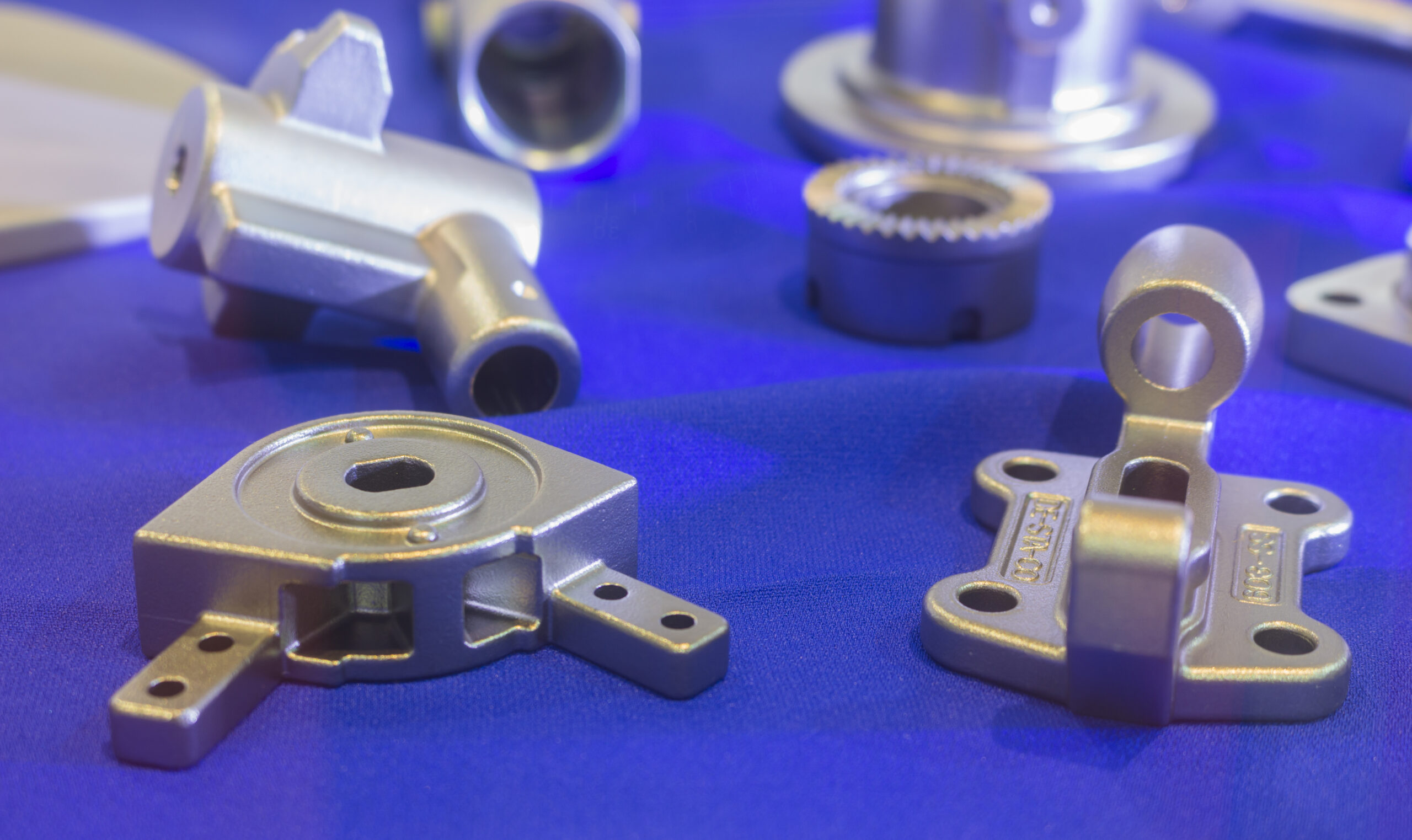

The Investment water glass casting (also known as Lost wax casting) process is particularly suited to larger castings and is more cost effective.

Water glass cast components are mainly used where heavier or stronger, more complex shapes are required. Applications of this technique are widely presented in the production of trailers, agricultural machinery, material handling and in the offshore industry. The process provides a far superior surface finish and dimensional precision to that achieved through sand casting.

It is our most chosen and flexible castings process when changing weldments into castings.

WELD2CAST’s Investment Water Glass Casting Benefits Include:

- Suitable for size castings ranging from 0,1 kgs to 50 kg.

- Very low tooling cost.

- Complex design without draft angles.

- Minimum wall thickness 4 mm.

- Higher accuracy in comparison to sand casting with a superior surface finish.

- Environmental advantages.

- Most common alloys for the water glass process is carbon steel in high and low alloys, like Gs20Mn5, G26Mn5, G25CrMo4, G35CrMo 20CrNiMo, G42CrMo4 and many mores.