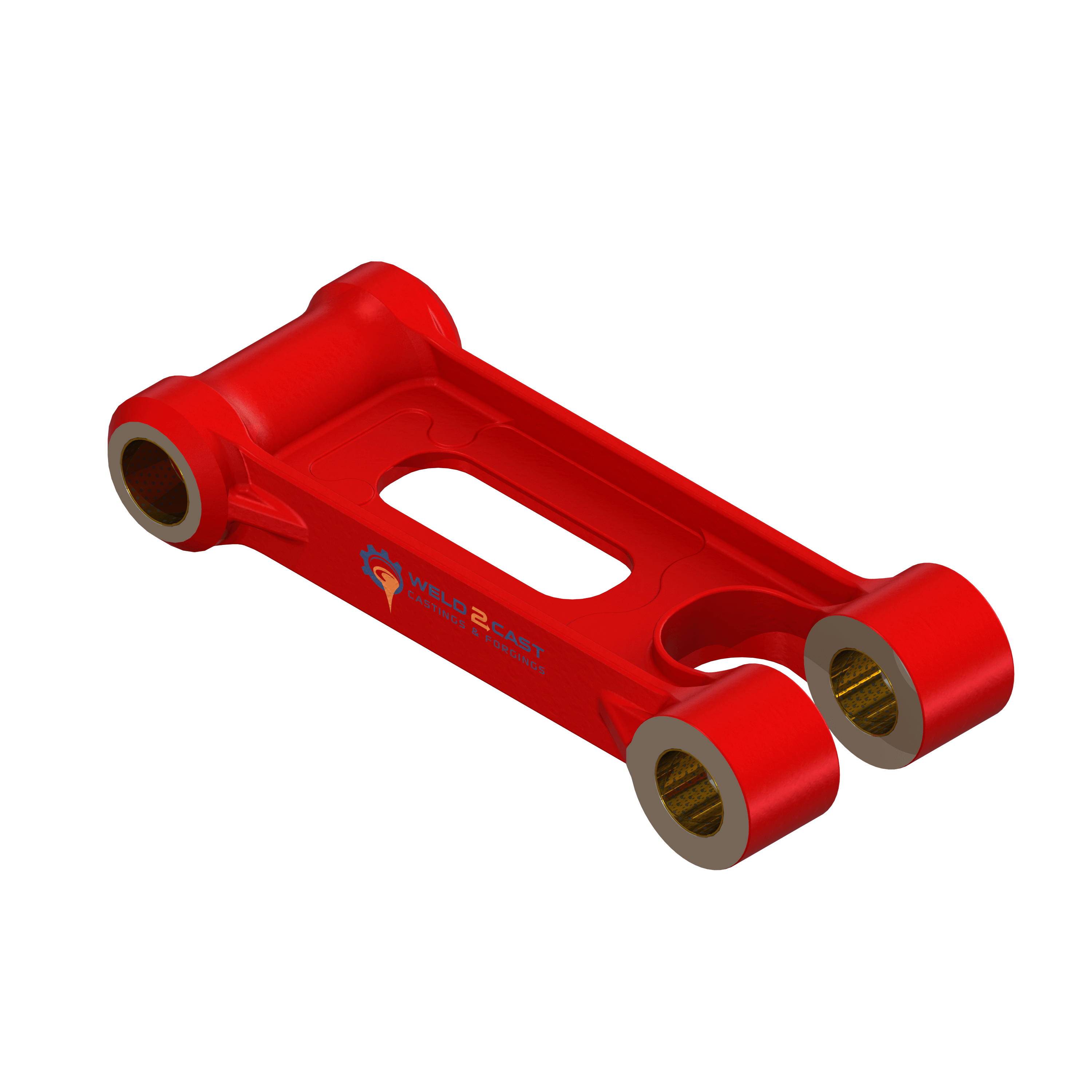

Casting Of Components

CNC Machining of Castings

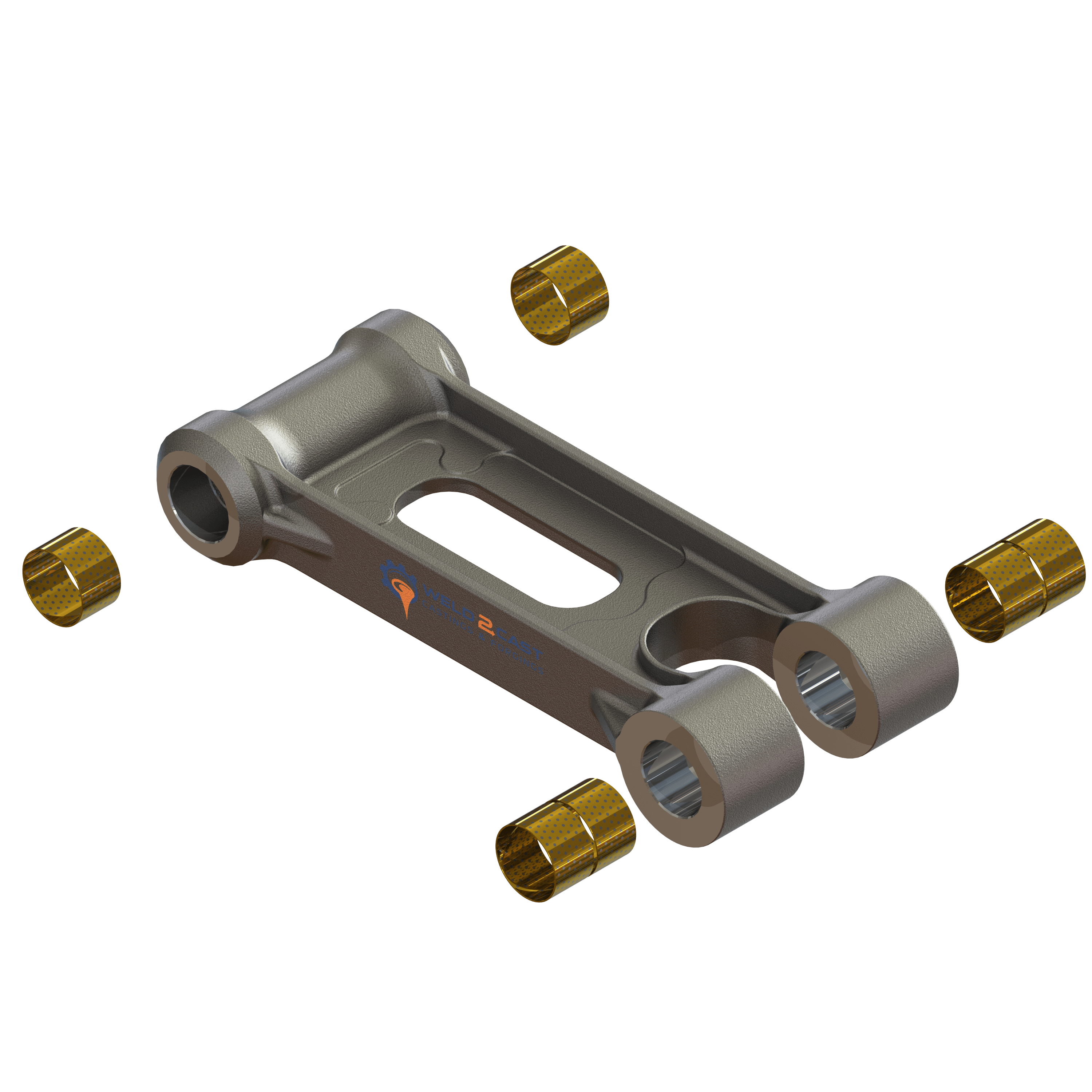

Assembling process with (6x)

plain bronze bearings pressed in.

Surface finishing

(Powder Paint Coating)

Shipment of finish painted and assembled components to costumer's production line.

[timeline-express]

| UK Investment Casting | Outsourced Investment Casting | Outsourced Sand casting | Outsourced Gravity die casting | Outsourced Pressure die casting | Outsourced Forging | |

|---|---|---|---|---|---|---|

| Weight range achievable (kg) | 0.01 - 25 | 0.01 - 75 | 1 - 500 | 0.5 - 25 | 0.01 - 25 | 0.03 - 25 |

| Typical Unit Volume per year | 250 - 5,000 | 250 - 100,000 | 1 - 5,000 | 100 - 50,000 | 5,000 - 1,000,000 | 10,000 - 100,000 |

| Pattern / tooling cost | Moderate | Low | Low | Moderate | High | Moderate |

| Cost of Tooling change | Moderate | Low | Low | Moderate | High | Moderate |

| Flexibility of design | Excellent | Excellent | Very high | High | Relatively high | Low |

| Minimum wall thickness, mm | 0.5 | 1 | 3 | 2.5 | 1 | 2 |

| Finishing Costs | Low | Low | High | Low - Moderate | Low | Low - Moderate |

| Dimension accuracy, Tolerances in accordance with ISO 8062 | CT4 - CT6 | CT5 -CT7 | CT9 - CT10 | CT 6 - CT8 | CT4 | CT5 - CT6 |

| Draft Angle Needed (deg) | 0 - 0.5 | 0 - 0.5 | 2 | 2 | 0.5 - 1 | 1 - 2 |

| Surface finish (Ra) | 3.2 | 3.2 | 6.3 | 3.2 | 1.6 | 1.6 |

| Casting alloy Bases | Carbon Steel | Carbon Steel | Cast Iron | Aluminium | Aluminium | Aluminium |

| Stainless Steel | Stainless Steel | Aluminium | Brass | Copper Base | ||

| Monel | Monel | Zinc | Stainless Steel | |||

| Cobalt Chrome | Cobalt Chrome | Carbon Steel | ||||

| Brass | Brass | |||||

| Bronze | Bronze | |||||

| Duplex Stainless steel | Duplex Stainless steel | |||||

| Aluminium | Aluminium | |||||

| Precipitation Stainless Steel | Precipitation Stainless Steel | |||||

| Hastelloy | Titanium | |||||

| Hastelloy | ||||||

| UK Investment Casting | Outsourced Investment Casting | Outsourced Sand casting | Outsourced Gravity die casting | Outsourced Pressure die casting | Outsourced Forging |